Roof & Wall

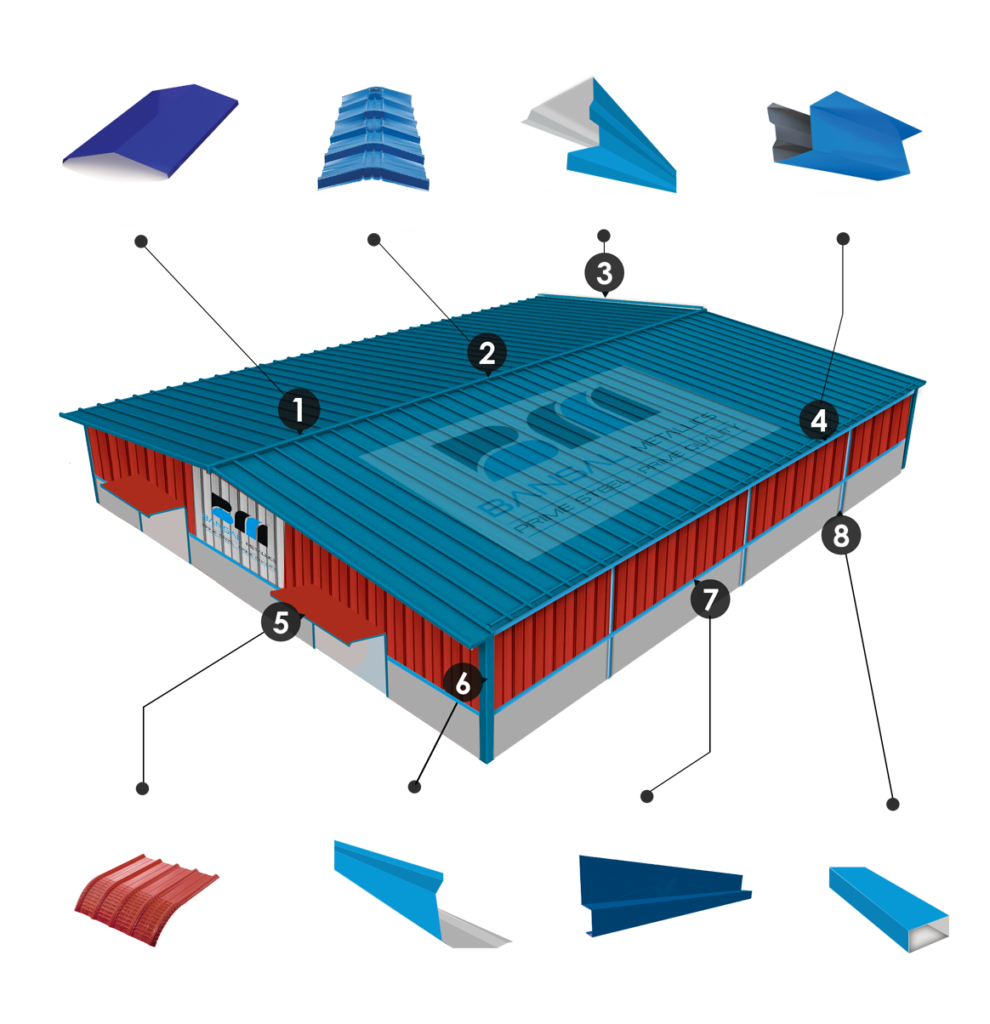

Roof and Wall Sheeting

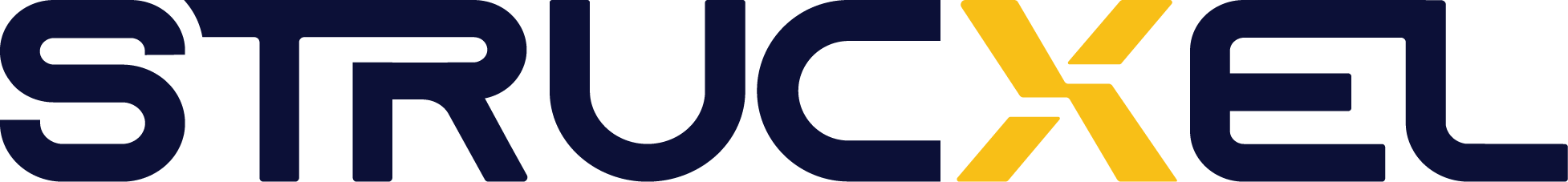

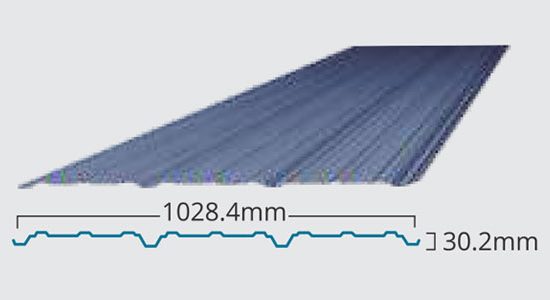

Panels used for sheeting purposes are typically ribbed steel sheets utilized for roof and wall sheeting, liners, partitions, and soffit sheeting. These sheets are generally made from steel coils with a thickness ranging from 0.47 mm to 0.8 mm of high-tensile steel. Today, the newly developed type “S” panel is widely used. Its profile is designed to withstand heavy loads, such as roof snow loads and uplift loads from high-velocity (cyclonic) winds. The panel conforms to ASTM A792M Grade 340/550 MPA and is coated with Galvalume, a protective layer consisting of 42.5% zinc and 55% aluminum alloy (150 GSM). Panels are available in four nominal thicknesses: 0.475 mm, 0.50 mm, 0.55 mm, and 0.76 mm, and in all standard colors.

Claddings

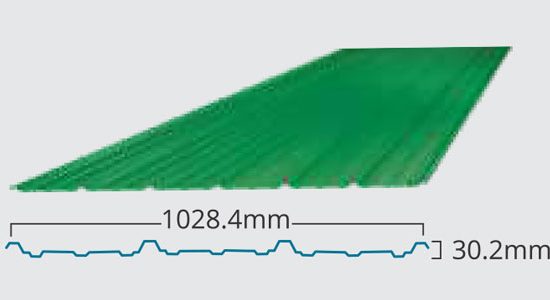

Strucxel’s pre-painted Galvalume (Alu-Zinc) sheeting features a multi-layer coated profile, ensuring longer life under various weather conditions and enhanced aesthetics. These claddings can be used for roofs and walls and are available with or without insulation.

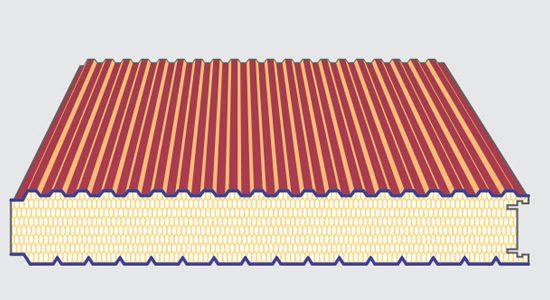

PUF Panels

These are roof and wall skins (sheeting) that cover the main steel frame. Sandwich panels consist of an exterior metal skin, a polyurethane core, and an interior flat metal skin. The core thickness options include 35 mm, 50 mm, 75 mm, and 100 mm, with a polyurethane density of 35-40 kg/m³.

The Strucxel Advantage:

- Offers roof options with slopes as low as 1:10

- Width: 1028 mm | Length: up to 12 m | Thickness: 30 mm

- Purlin-bearing edge enhances strength and sturdiness

- Provision for fiberglass and other insulation

- A range of energy-efficient roofing solutions

In most cases, Strucxel uses a simple one-coat application (35 microns) of red oxide paint for both primary and secondary steel members. This is sufficient for typical projects. However, for situations requiring enhanced corrosion resistance, Strucxel employs a more rigorous approach. Here, the steel undergoes a process called shot blasting, which removes impurities and creates a textured surface for better paint adhesion. Following this, a specialized paint with superior anti-corrosive properties is applied.

For doors and windows in Strucxel’s projects, frames made of steel or aluminum are secured to the supporting structure. This can be done in two ways: welding them directly to the purlins (curved metal beams) or bolting them to flanges already attached to the purlins. Whichever method is chosen, strategically placed flashings are installed to ensure a watertight seal and prevent leaks.

Many homes and offices benefit from the use of false ceilings. These are created by suspending a metal framework from the existing ceiling. Rigid panels are then either secured to this frame with bolts or simply rest on top, creating a finished lower ceiling.

In pre-engineered buildings, builders often incorporate curved eaves for a touch of visual appeal. These eaves are crafted from sheets of colored steel that are shaped through a process called crimping. This crimping adds a decorative element and helps the steel hold its curved form.

Contact With Us

- Pre-Engineered Buildings (PEBs)

- Structural Steel Construction

Have any question

+91 96873 59519